A Large-Scale bottle flake washing plant, with an annual output ranging from 50,000 to 200,000 tons, not only needs to maintain stable production over an extended period but also seeks to improve product profitability by increasing feedstock volume and enhancing product quality!

Is there truly sorting equipment that combines exceptional sorting performance with high cost-effectiveness?

01 Stability

How can we maintain stability with continuous 24-hour operation?

-

Our AI Optical Sorter is equipped with German-imported SEW motors

-

Japanese-imported NSK bearings

-

350-type metal roller shafts

-

high-speed conveyor belts resistant to extreme temperatures, which are suitable for environments ranging from -30 to +50 degrees Celsius.

-

The electrical control system and valve group system has an IP65 protection level, and they are designed to stably operate in harsh working environments, such as water vapor, acidic substances, and fine dust.

-

Thirty years of industry experience to solve belt deviation issues.

02 Accuracy

The sorting accuracy reaches over 99.6%

-

The new sixth-generation large-scale optical sorter is equipped with a super-clear line-scan camera, which has ultra-high resolution and can identify subtle differences in various materials

The laser line-scan camera, capable of identifying subtle color differences, with superior recognition of light blue shades.

-

Equipped with top-tier computational power and cutting-edge deep learning recognition algorithms in the industry.

-

Equiped with hyperspectral sensors, fluorescence sensors, metal sensors, laser sensors, X-ray sensors

Using fluorescence sensors, fluorescent bottles and aged bottles are directly removed, with fluorescent pieces controlled within 10 PPM, easily achieving high-quality 3A grade.

Using a hyperspectral sensor, 256 spectral bands are recognized to detect material differences with precision, leaving no room for subtle material discrepancies.

03 Fast

What is the significance of a processing capacity of 10 tons per hour?

The larger the processing capacity of the Optical Sorter, the lower the cost per unit, reduced losses, energy and labor saving. Most importantly, it saves money, helping bottle factories greatly enhance their market competitiveness.

123 2 tons/hour 143 3 tons/hour 183 4 tons/hour

"Cost-effective, compact, and easily portable."

-

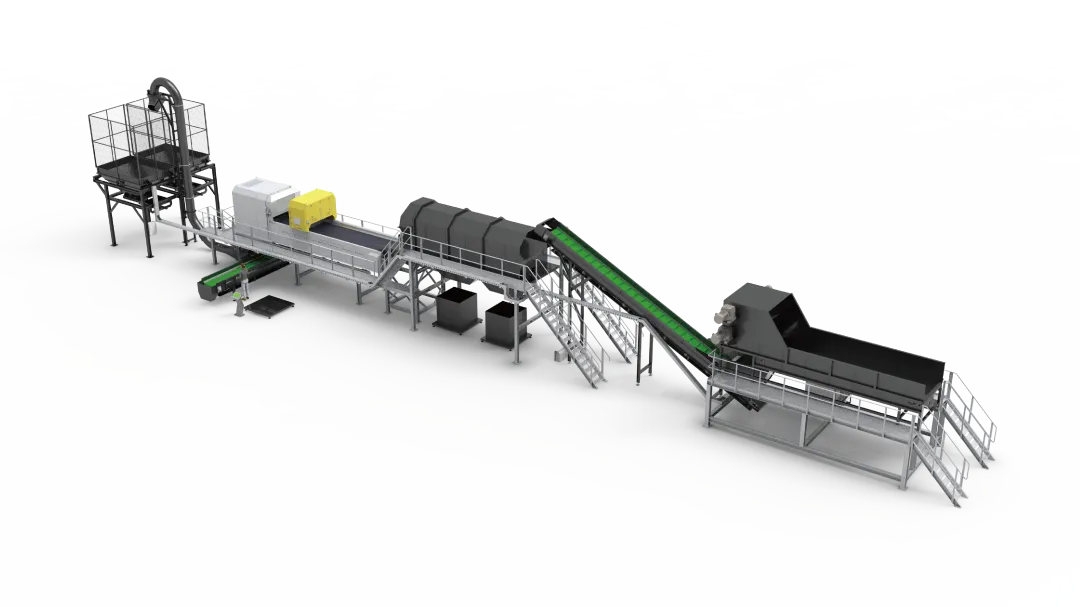

IQC Line Of Plastic Bales:By integrating weighing, unpacking, impurity removal, quality inspection, and impurity weighing into a single step, only one person can efficiently conduct quality inspections, gather inspection data, and automatically price raw materials based on inspection results. This segregation of roles prevents corruption by separating quality inspectors, receivers, and production staff.

IQC Line Of Plastic Bales

Top Perfromance Of Product Combination for Recycling Manufacturer to Establish "Dark Factory"

The mainline utilizes Large AI Optical Sorter to select white and blue, ensuring stability and reliability.

The Mini AI Optical Sorter for secondary sorting of miscellaneous materials is cost-effective and reduces labor costs.